Automatic spraying line for workpiece rotation

Fitting accessories:Buttons, handle, decorative parts, wheels, small accessories, etc.

Spray method:Multi joint manipulator, coordinate manipulator, fixed gun type, (can be stopped spray, spray can be traced)

Baking method:Tunnel bypass type oven with far infrared heating IR lamp;

Coating environment:Painting room 10000 level, workshop level one hundred thousand, and the constant temperature and humidity adjustable;

Yield:Depending on the work of the workpiece and the baking time of the coating combined with the linear velocity

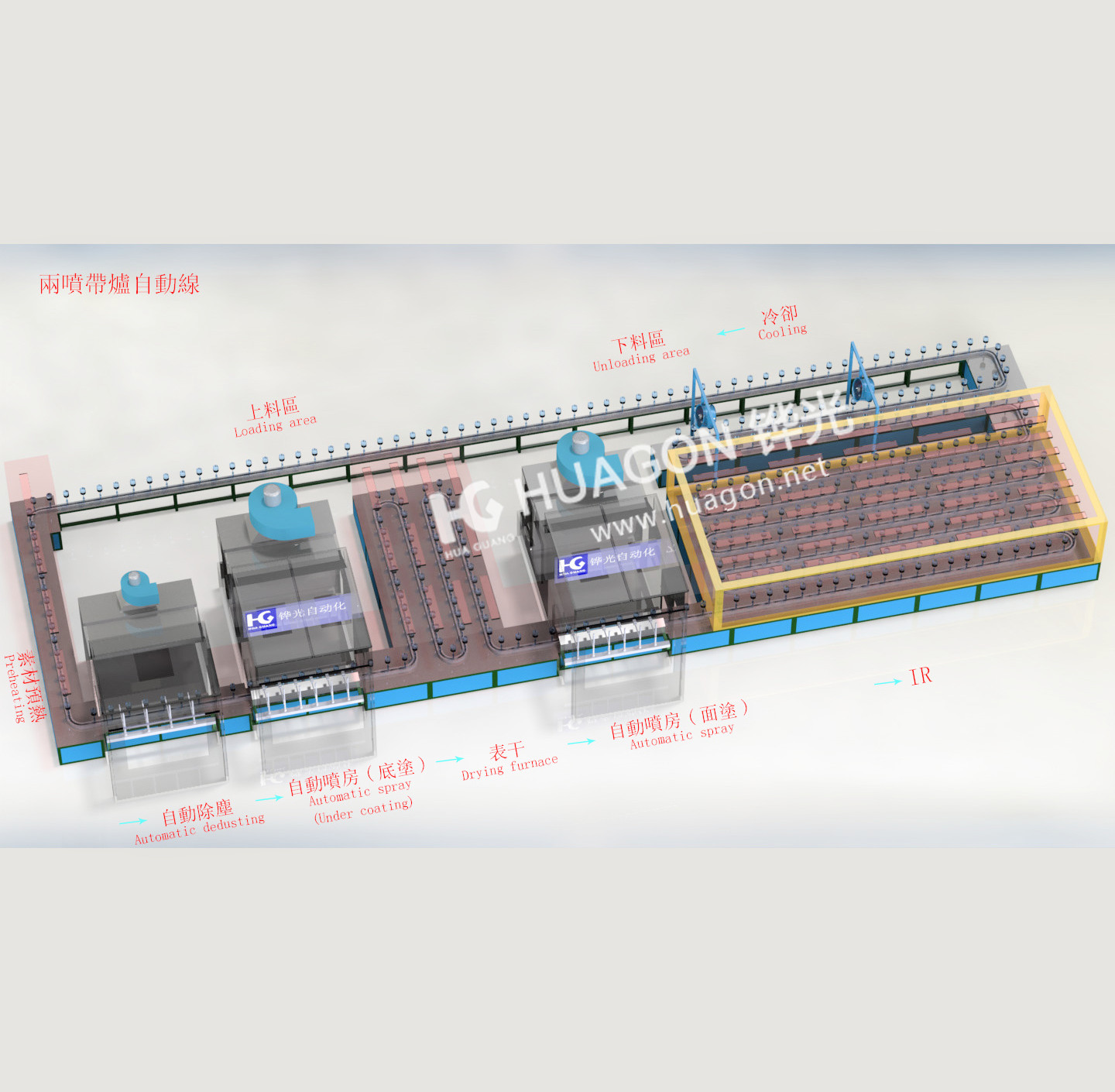

Technological process:(take two baked two)

Clamping, on-line, manual, automatic electrostatic precipitator and electrostatic precipitator preheating dehumidification 5min (50 degrees C), automatic electrostatic spray, priming, leveling 11min (room temperature), 30min (primer curing room temperature -80 degrees C), natural cooling 5min, spray paint, leveling 12min (room temperature), 66min (normal temperature curing -80 ~ C), 15min, cooling parts inspection