Metal electrostatic spraying line

Fitting accessories:Spraying of irregular objects such as tables, stools, bicycles, categories, etc.;

Spray method:Multi joint manipulator, coordinate manipulator, fixed gun type, (can be stopped spray, spray can be traced)

Baking method:Tunnel cyclotron, using biomass pellet combustion machine;

Coating environment:Sealed, no special treatment

Yield:Depending on the work of the workpiece and the baking time of the coating combined with the linear velocity

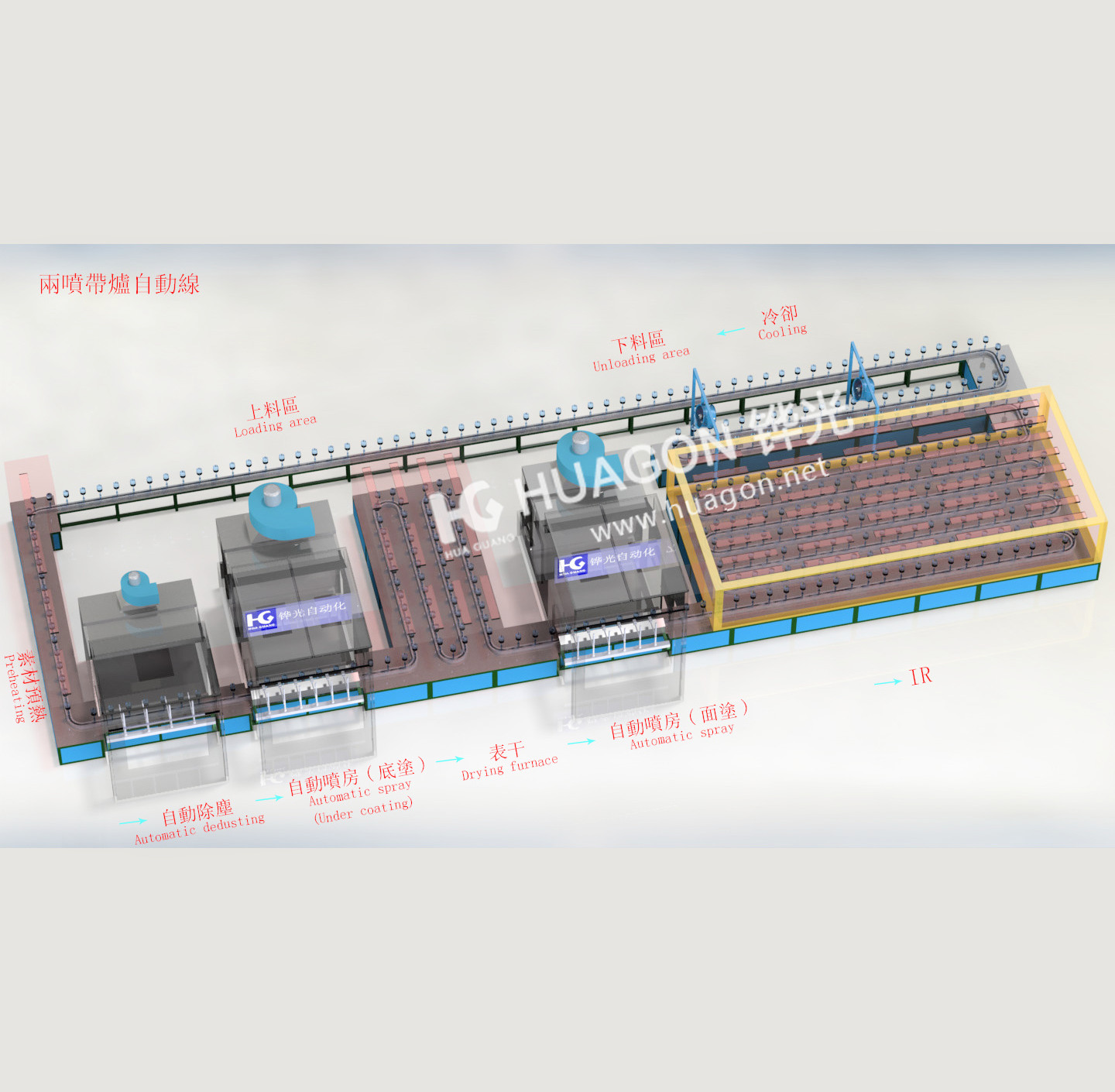

Technological process:

The upper part, pre absorbent, water forced skim, surface adjustment, phosphating, water washing (automatic spraying), dehydration, multi task station, manual / automatic spraying, static, baking, cooling and unloading.

According to different parts of different processes, such as wood and metal with different pretreatment in spraying concrete depending on demand;