Automatic spraying line for workpiece rotation

Fitting accessories:Mobile phone, IPDA, mobile hard disk, mobile hard disk, camera, coffee machine, hot water pot and other small accessories;

Spray method:Multi joint manipulator, coordinate manipulator, fixed gun type; (can be stopped spray, spray can be traced)

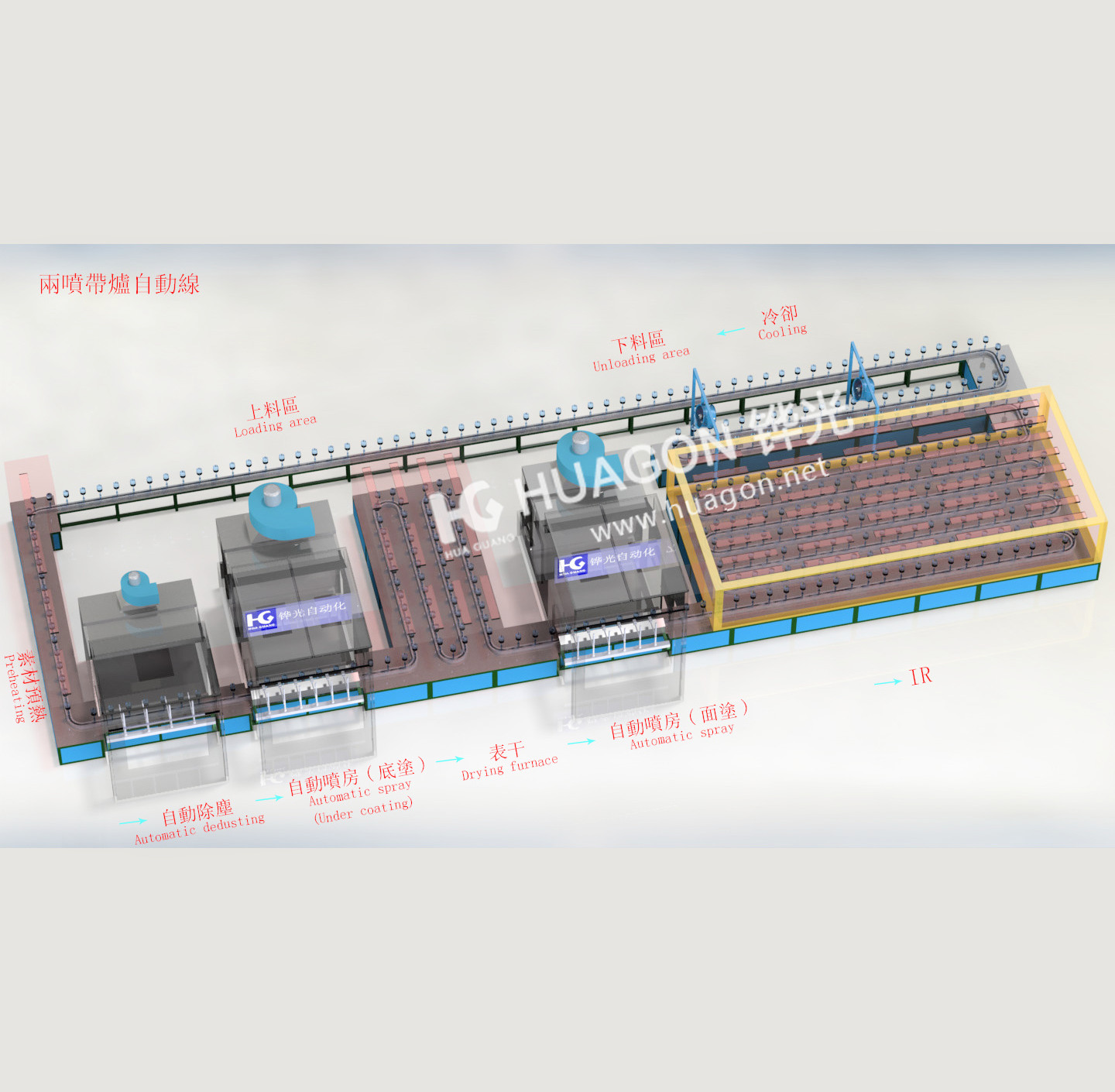

Baking method:Tunnel bypass type oven with far infrared heating IR lamp;

Coating environment:Painting room, workshop one hundred thousand;

Yield:Depending on the work of the workpiece and the baking time of the coating combined with the linear velocity

Technological process:The multifunctional three Tu three grilled for example, this line can be connected with the split to adapt to the current market, all the common process, such as: rubber paint, metal paint, PU paint, primer, paint, ordinary ordinary UV paint, vacuum plating, etc.

Multi functional application:Can be split into three lines, can be split into two lines, can be connected to a line;

Two coating: coating, rubber paint coating / feeder

Two Tu UV paint: in the paint - -->UV surface coating

Three coating UV paint: primer - Coating -- -->UV -- > feeder connected surface coating

Paint line: material - > manual removal - > - > - > automatic electrostatic dust material preheating water spraying preheating automatic spraying (1 - > - > primer) - > ->IR-> - > static cooling material

Paint line: material - > manual removal - > - > - > automatic electrostatic precipitator preheat material automatic spraying 2 (coating) - > ->IR-> - > static cooling material

Line UV: material - > - > - > automatic manual removal material preheating electrostatic precipitator (3 - > automatic spray paint) - > static ->IR-> ->UV > > cooling cooling curing material